- Technique:

-

Chopped Strand Fiberglass Mat (CSM)

- Mat Type:

-

Stitch Bonding Chop Mat

- Fiberglass Type:

-

E-Glass

- Softness:

-

soft

- Place of Origin:

-

Hebei, China

- Brand Name:

-

HUILI

- Weight:

-

20—85kg

- Width:

-

1040/1270mm

- Binder Type:

-

Emulsion Power

- Moisture Content:

-

0.20%

- Tensile strength:

-

80 N/150mm

- Color:

-

White

250g-600g E glass Fiberglass chopped strand mat for panels

1.Description Of Chopped Strand Mat:

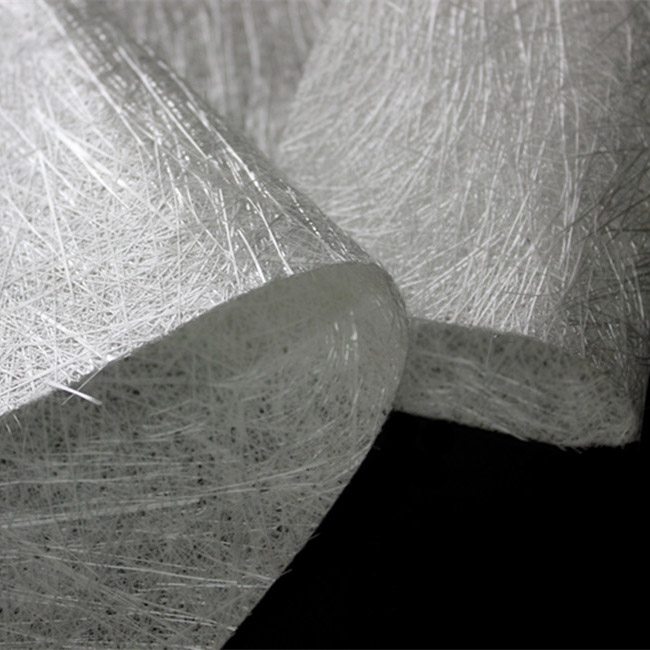

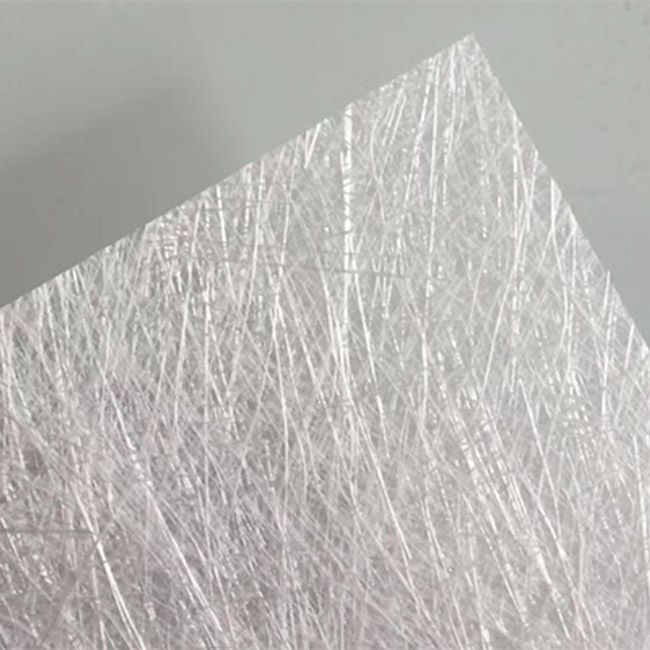

Fiberglass Chopped Strand Mat is kinds of reinforcing products that made from continuous fiberglass strand, which is chopped into a certain length, distributed in a random and non-directional position and bonded with binders. It is suitable for hand lay-up. Mold press, filament winding and mechanical forming etc., such GRP processes. The main products include kinds of panels, boats, bath equipments, automobile parts and cooling towers etc.

Explaination Of Some Noun:

EMC:Product type

1.EMC:E-glass Chopped Strand Mat(Powder)

2.EMC:E-glass Chopped Strand Mat(Emulsion)

3.CMC:C-glass Chopped Strand Mat

2.Simple Size Of Chopped Strand Mat:

| Style | Mass(g/m2) | Tensile Strength(N/50m) | Combustible Matter Content | Width(CM) | Wet-out Rate(s) | Moisture Content | |

| Longitudinal | Transverse | ||||||

| EMC100 | 100±22 | ≥30 | ≥30 | 1.8%-8.5% | 1040/1270 | ≤40 | ≤0.20% |

| EMC200 | 200±22 | ≥40 | ≥40 | ≤60 | |||

| EMC300 | 300±22 | ≥60 | ≥60 | ≤80 | |||

| EMC375 | 375±20 | ≥60 | ≥60 | ≤80 | |||

| EMC450 | 450±20 | ≥80 | ≥80 | ≤100 | |||

| EMC600 | 600±18 | ≥80 | ≥80 | ≤100 | |||

3.Feature of Chopped Strand Mat:

- Consistent thickness and stiffness

- Rapid impregnating and good compatibility with resin

- Superior wet through with less air trap

- Good mechanical properties and high strength of parts

- Good cover mold, suitable for modeling complex shapes.

4.Usage Of Chopped Strand Mat:

The Usage of EMC 450g Fiberglass Chopped Strand Mat for epoxy resin

- Automobile accessories

- Plumbing fittings

- Chemical anticorrosive pipeline

- Cooling towerBasin

- Boats and ships

- Building

- Furniture

It’s mainly used in hand lay-up, filament winding and compression molding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.

Uniform thickness, softness and hardness good.

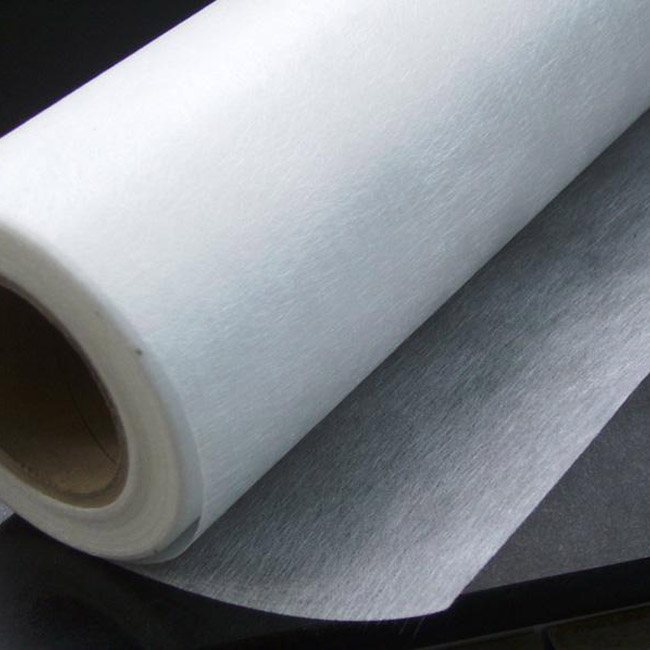

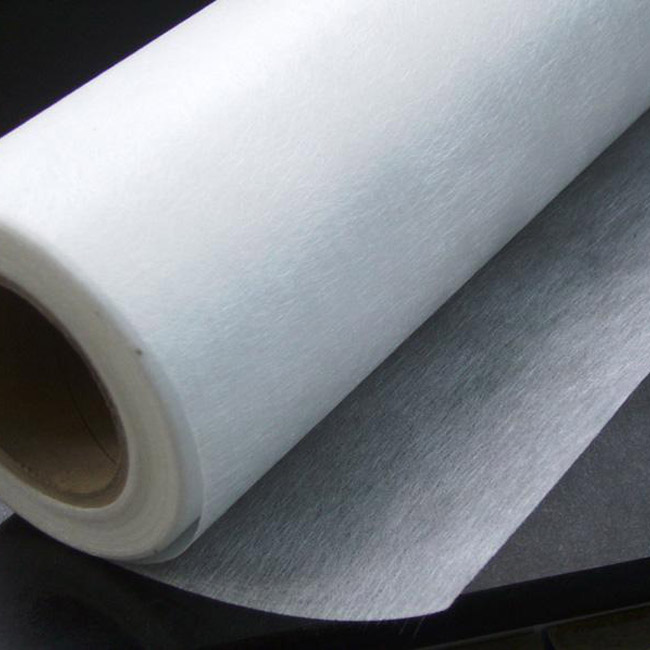

5.Storge And Packaging

- Each roll is packed by polyester bag and then put into a cardboard box or plastic woven bag.

- The weight if each rill is between 20—85kg.

- The rolls are to be horizontally placed and could be in bulk or on pallet.

- Optimum storage conditions are between the temperature of 5—35℃ and with the humidity between 35%—65%.

- The Product should be used within 12 mongths from the time of delivery and remain in theiroriginal packaging until just prior to use.

1.Q: Can you offer a piece of sample for us ?

A: In order to present our sincerity, we can offer free sample for you ,but express charges need to stood by your side first.

2.Q: Are you a manufacturer oa trading company?

A: We are factory,located in Wuqiang County,Hengshui City,Hebei Province,China

3.Q:Could i get a discount?

A: If your quantity is more than our MOQ, we can offer a good discount according to your exact quantity. we can ensure that our price is very competitive in the market based on good quality.

4.Q: Can you finish the production on time?

A: Of course,we have large production line,will delivery the goods on time.

5.Q: How about your delivery time?

A: according to your order quantity.

About us:

A: More than 150 employees

B: 100 sets of woven machines

C: 8 sets of PVC fiberglass yarn production lines

D: 3 sets wrapping machines and 1 set high-end steam setting machine

Our Advantages:

A.We are the real factory ,price will be much competitive,and delivery time can be assured !

B.The package and lable can be done as your requirements ,we pay attention to details

B.We have the first class machinery and equipment from Germany .

C. We have professional Sales team and best after sale service team .

-

Powder Binder Fiberglass Chopped Strand Mat for...

-

E-glass Custom Epoxy Resin E-glass Fiberglass C...

-

Powder Emulsion Material E-glass Fiberglass Cho...

-

Powder Material 450g fiberglass chopped strand ...

-

E-glass 600g Fiberglass Chopped Strand Mat for ...

-

fiberglass mat glass fiber tissue chopped stran...